Formwork | Requirements of a good formwork | Types of formwork | Formwork detail for different structural members | Cost of formwork

What is Formwork

Formwork is temporary molds into which concrete or similar materials are poured. In the context of concrete construction, counterfeiting supports formwork molds.

Requirements of a good Formwork

It must be rigidly built and efficiently propped up and propped up both horizontally and vertically to maintain its shape.

The formwork must allow the removal of various parts in desired sequences without damaging the concrete.

The formwork must be precisely adjusted to the desired line, and the levels must have a flat surface.

It must be strong enough to withstand all kinds of dead and live loads. The joints in the formwork must be tight against cement grout leaks.

Formwork material must be cheap, readily available, and suitable for reuse.

The formwork must be precisely adjusted to the desired line, and the levels must have a flat surface.

It should be as light as possible. Formwork material should not warp or deform when exposed to the elements.

It must rest on a firmbase.

Types of Formwork

Wooden formwork consists of

Props

Planks battens

Ledgers sheeting

steel sheets

Angle Iron

Tee Iron

Formwork detail for different structural members

In concrete construction formwork is commonly provided for the following structural members like given below:

Foundations

Wall Column Slabs

beams

Stairs

Formwork for Foundation

The first step for any concrete construction begins with the construction of the foundation.

Foundations can be for columns or walls. Therefore, depending on the type of structural member, the shape and size of the footing are designed.

Therefore, the size and shape of the formwork depend on the type and dimension of the footing.

Formwork for wall

one side of formwork reinforcement is provided in the then place the second side the formwork is provided.

Formwork for Column and Beam

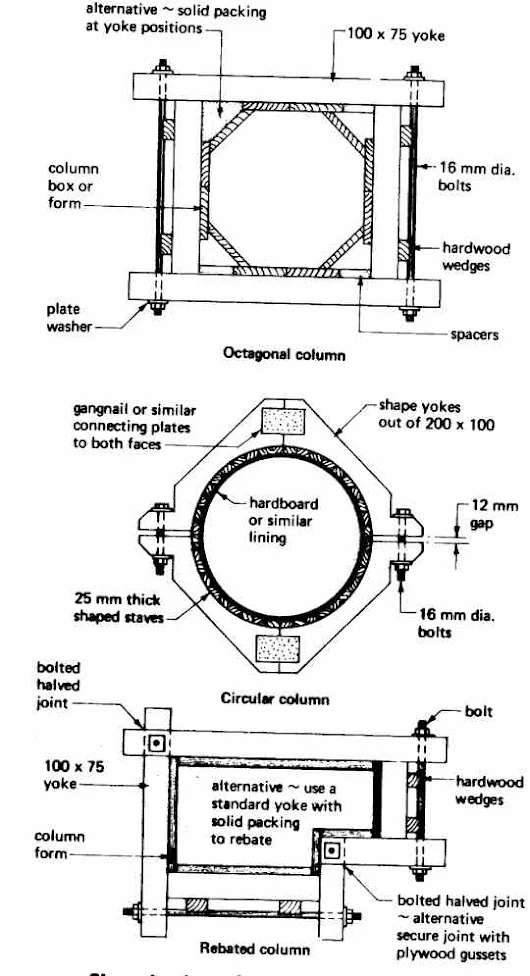

Column formwork Two ends and two sides the planks are joined by yokes and bolts.

Beam formwork rests on the head of the tree Slab Work Slabs in slats and joists If the strut height is over 8 "provide Horizontal straps.

Formwork for stairs

Advantages of steel formwork

Very strong and capable of carrying heavy load.

Easy to fix.

Irregular size and surface. It can be used for a long times.

Disadvantages of steel formwork

Limited size or shape.

Excessive heat loss.

A very smooth surface will be produced which would cause problems for the finishing process.

Advantages of wooden formwork

Easy handling because it is light.

Easy to disassemble.

Damaged parts can be replaced with a new one.

Very flexible.

Disadvantages of wooden formwork

It cannot be used for a long times.

It has limited reuse. It can only be reused 5 or 6 times.

If the wood is dry, it will absorb moisture from the wet concrete, which could weaken the resulting concrete member and cup leading to open joints and grout leaks.

Cost of formwork

For normal work, the cost of the formwork is approximately 30% -40% of the cost of concrete.

For special works the cost of the formwork is approximately 50% -60% of the cost of concrete.

The cost of the formwork is controlled by the following factors Formwork material cost Formwork assembly cost Formwork removal cost Cost of formwork joints (nails and cables) Labor charges.